Lateral Flow Automation Production Lines: A Game Changer for POCT Solutions

Sep 07, 2024|

Sep 07, 2024| View:25

View:25

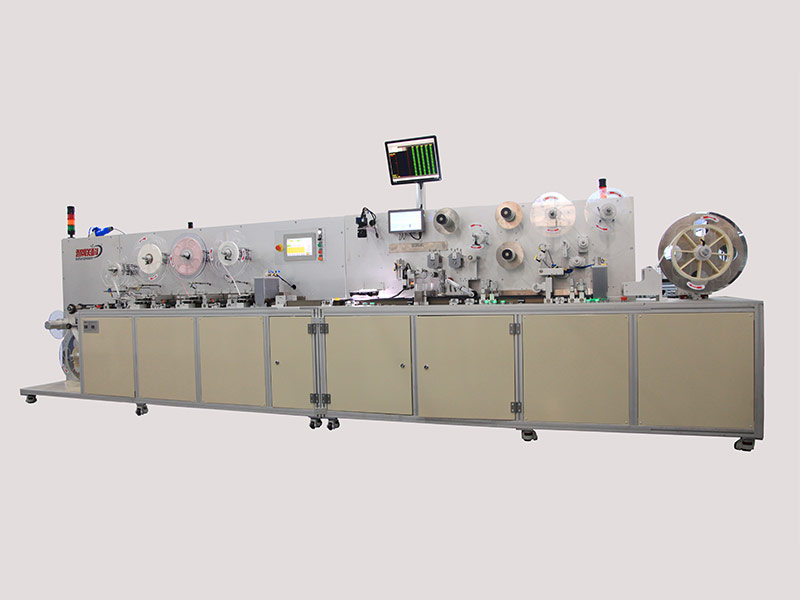

Lateral Flow automation production lines play a crucial role in point-of-care testing solutions. These production lines utilize advanced technology to ensure the efficient and accurate manufacturing of lateral flow tests. POCT Roll Automation further enhances the process by automating the handling of test strips, reducing human error and increasing productivity. With the increasing demand for rapid and accurate diagnostic tests, these technologies are becoming essential in the healthcare industry. For example, automation has reduced the work force by up to 50% in some factories, as seen in the case of Honda's production line addition this year. This not only cuts costs but also improves the quality and consistency of the products.Reel to reel laminator machines play a crucial role in Lateral Flow automation production lines and POCT Roll Automation,which provides new POCT solutions.

Advantages of Lateral Flow Automation Production Lines

Enhanced Efficiency and Productivity

Lateral flow automation production lines significantly increase efficiency and productivity. With advanced technology, tasks that were once done manually can now be completed at a much faster pace. For instance, translational processing by way of style duplex can double the increase production efficiency. This means more test kits can be produced in a shorter amount of time, meeting the growing demand for point-of-care testing devices.

Improved Quality Control

Automation plays a crucial role in ensuring consistent quality of test kits. By minimizing human error, these production lines can produce test kits with a higher degree of accuracy. For example, automation equipment can precisely measure and dispense reagents, ensuring that each test kit has the correct amount of necessary components. This leads to more reliable results and greater confidence in the diagnostic process.

Cost-Effectiveness

In the long run, automation can lead to cost savings. Although there may be an initial investment in setting up an automated production line, the benefits quickly outweigh the costs. Reduced labor costs, increased productivity, and improved quality control all contribute to cost-effectiveness. As seen in many industries, automation has the potential to cut costs by a significant margin. For example, in the last ten years, automation has reduced the work force here by half, resulting in substantial savings on labor expenses.

Applications of POCT Roll Automation

POCT Roll Automation finds extensive use in a variety of medical settings. In hospitals, it streamlines the diagnostic process, enabling quick and accurate testing. For instance, in emergency departments, it can provide rapid results for conditions that require immediate attention. In clinics, it enhances the efficiency of routine check-ups and disease monitoring. In medical settings, active, direct and vivid language can make the humanistic care in medical practice and the humanistic nature of medicine deeply felt. Just as in the case of automated lateral flow tests, POCT Roll Automation reduces human error and increases productivity, ensuring reliable results.

Reel to Reel Laminator Machines for POCT

Importance in Production

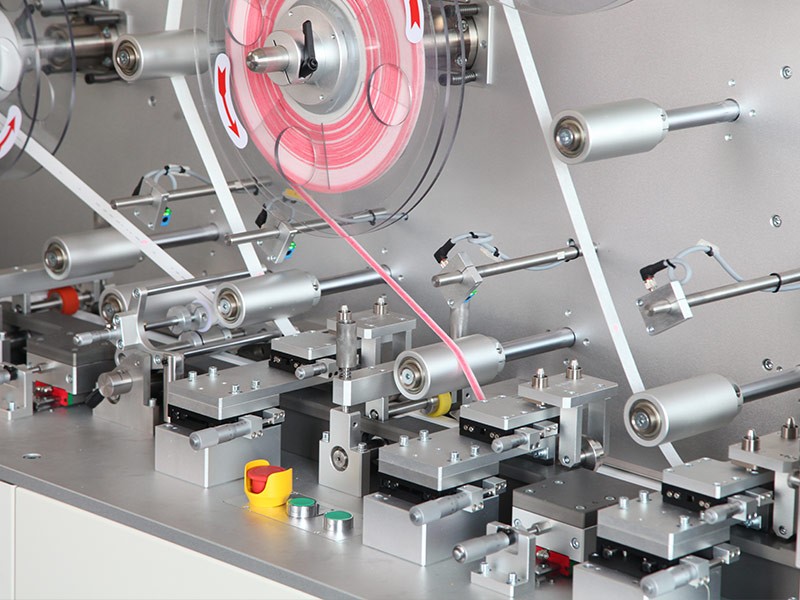

Reel to reel laminator machines play a crucial role in the production of POCT devices. They ensure the proper adhesion and protection of the various components of the test strips. Without these machines, the production process would be less efficient and the quality of the final product could be compromised. For example, in the production of lateral flow tests, the laminator machine helps to seal the test strips, preventing any leakage of reagents and ensuring accurate results.

Features and Benefits

These machines offer several unique features and benefits. One of the key features is their precision. They can apply the laminate with great accuracy, ensuring a consistent thickness and quality. This precision is essential for the proper functioning of the POCT devices. Another benefit is their speed. Reel to reel laminator machines can process a large number of test strips in a short amount of time, increasing productivity. Additionally, these machines are often designed to be user-friendly, with easy-to-operate controls and minimal maintenance requirements. For instance, some models come with automated settings that can be adjusted according to the specific needs of the production process. The benefits of using reel to reel laminator machines extend beyond just the production process. They also contribute to cost savings in the long run. By ensuring high-quality production and reducing waste, these machines can help manufacturers lower their production costs. Moreover, their reliability and durability mean that they can be used for a long time, providing a good return on investment.

In conclusion, automation is set to revolutionize point-of-care testing solutions in the coming years. With its many advantages, including enhanced efficiency, improved quality control, and cost-effectiveness, it is no wonder that more and more healthcare providers are turning to automated POCT devices. And if you need a reliable Reel to reel laminator machine, contact IntelUnion.

EN

EN CN

CN ES

ES FR

FR